Aluminum is a popular material for many items because it is strong yet lightweight. This makes it perfect for products that need to be durable but easy to transport, such as pots and pans. It is also non-toxic, meaning safe to use in food preparation. Finally, aluminum is an affordable option, making it a popular choice.

Casting is a popular process for forming aluminum because it is versatile and efficient. Casting can be used to create intricate shapes and is perfect for high-volume production. Here are five reasons why aluminum casting is so popular

Strength: Aluminum is a strong metal, which makes it ideal for casting. The strength of the aluminum alloy used in casting can be tailored to meet the project’s specific needs. Strength is key for any manufacturing company. Without a strong product, a company will not survive in the competitive market. This is why aluminum casting is so popular. Aluminum casting creates a strong product that can withstand the test of time. One reason aluminum casting is so popular is that it creates a solid product. The aluminum castings are much stronger than products made out of other materials. This means that they can withstand the wear and tear of everyday use. They are also less likely to break or malfunction.

Durability: Aluminum is also a durable metal, meaning that cast items made from it can withstand wear and tear. Durability is one of the key reasons aluminum casting is so popular. Cast aluminum parts are known for their toughness and resistance to wear and tear. They can withstand high temperatures and repeated impacts without sustaining damage. This makes them ideal for applications where reliability is essential, such as in transportation or manufacturing.

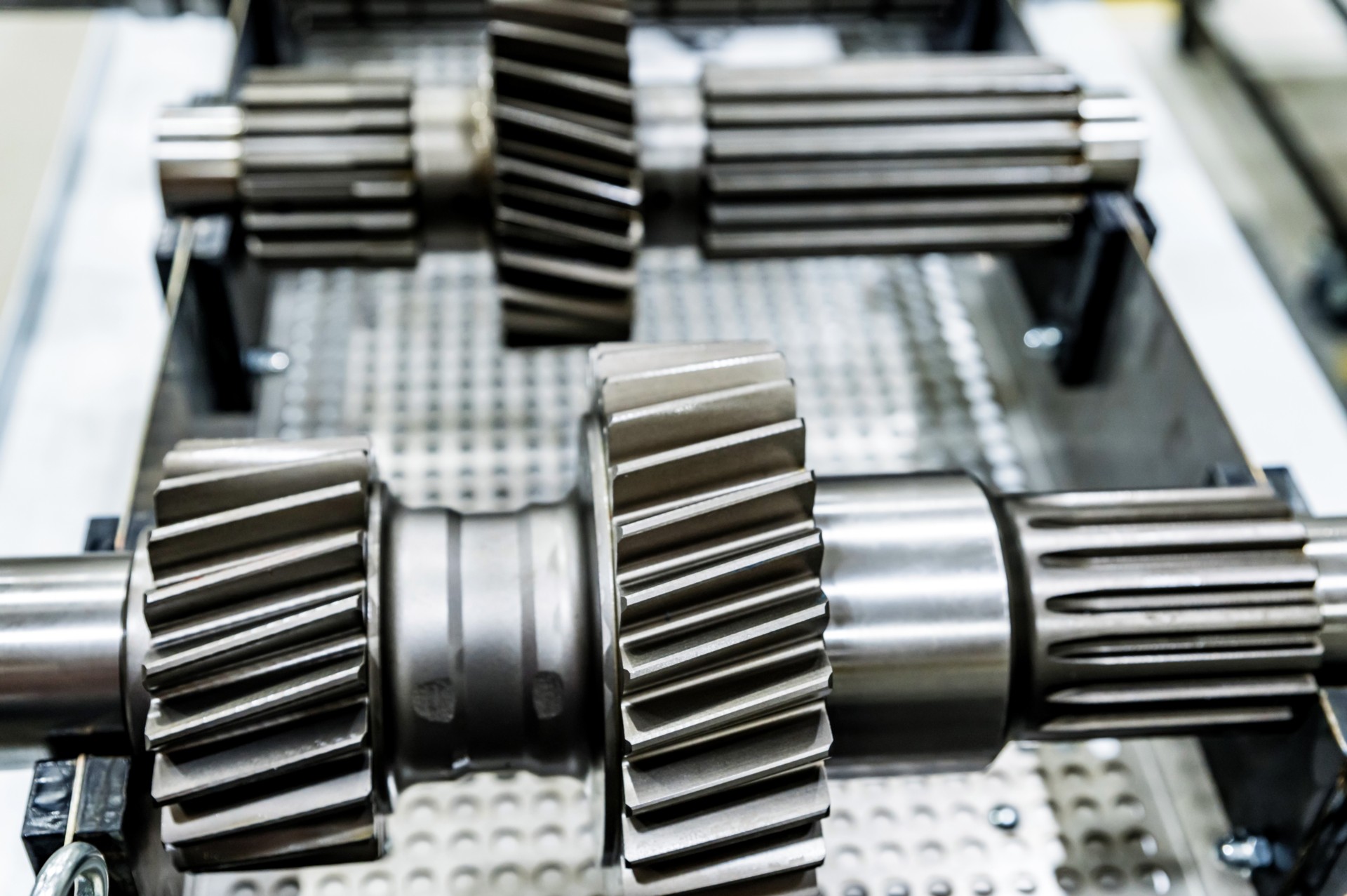

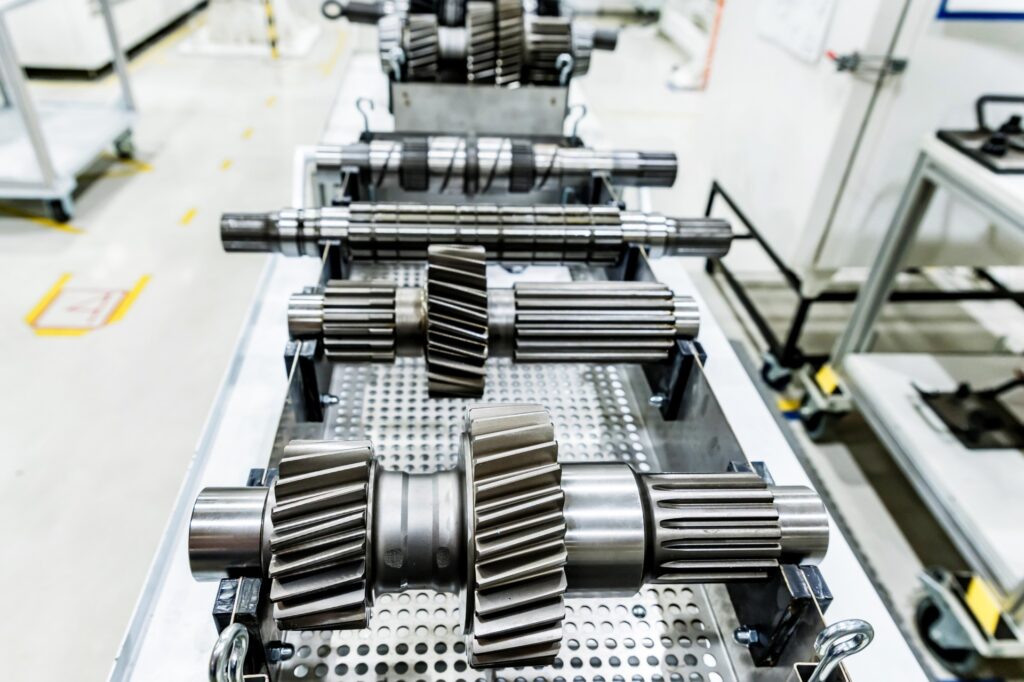

Versatility: Aluminum castings can be used in various applications, including everything from automotive parts to industrial machinery. That means companies are able to compete with other companies in the same niche.

Weight: Aluminum is much lighter than other metals, making it ideal for casting smaller parts. When casting aluminum, the weight of the casting is a significant consideration. The weight of an aluminum casting is affected by the alloy, the size and shape of the casting, and the method of manufacturing. The density of aluminum is 2.7 grams per cubic centimeter. The weight of an aluminum casting can be reduced by using a light alloy such as A380 or A356. The size and shape of the casting also affect weight. Some shapes are inherently heavier than others. Castings with thin walls are lighter than those with thick walls.

Cost Effective: Aluminum casting provides a relatively cost-effective way to create metal objects. Manufacturing parts and products out of aluminum is a very cost-effective process. This is because the material is light but strong, and it doesn’t corrode like some other metals. Casting aluminum parts can be done relatively quickly and easily, making it a popular choice for manufacturers.

There are different aluminum casting processes, but all of them have benefits that make them cost-effective choices for manufacturers. Die casting, for example, is a process that uses high pressure to force molten aluminum into steel molds. This produces high-quality parts with tight tolerances and consistent results.

Another cost-effective option for manufacturing aluminum is sand casting. In this process, sand molds are used to create the shapes of the parts that are being cast. This type of casting is very versatile, allowing the use of complex shapes and designs.